Vivimos una incesante etapa en la que la exploración espacial va tomando protagonismo. Todos hemos escuchado hablar de los vuelos comerciales en los que se pretende llevar a civiles al espacio o los ambiciosos proyectos de situar bases en la luna o en marte. Sin embargo, estos proyectos no se escapan de ser devorados por las llamas si no se toman las debidas precauciones.

Sigue leyendo Houston, tenemos un problema!Categoría: fire research

Second point to consider in fires of steel-framed buildings (3/11)

Emergency Response Plan

If we have knowledge about the emergency response plan we will be able to know where the hazardous areas are and what kind of materials are there accumulate inside the structure and we will know the protection fire system implemented in that area.

The first step when developing an emergency response plan is to conduct a risk assessment to identify potential emergency scenarios. An understanding of what can happen will enable you to determine resource requirements and to develop plans and procedures to prepare the building. The emergency plan should be consistent with your performance objectives.

At the very least, every facility should develop and implement an emergency plan for protecting employees, visitors, contractors and anyone else in the facility. This part of the emergency plan is called “protective actions for life safety” and includes building evacuation (“fire drills”), sheltering from severe weather such as tornadoes, “shelter-in-place” from an exterior airborne hazard such as a chemical release and lockdown. Lockdown is protective action when faced with an act of violence.

[youtube]oQxbyf2Z-MQ[/youtube]

The emergency response plan it’s an alive document, it means this document is always being updated by the responsible and the emergency services have to participate actively. This let emergency services have a deep knowledge of the situation in case of emergency.

But, what are the most important questions are we going to ask ourselves in steel-framed buildings to develop the emergency response plan?

- Fire load inside the structure and situation.

- Fire protection systems.

The first it’s the main point for emergency services because on this depends available time before the structure collapse.

In this link you will find an interesting guide to develop industry emergency response plans.

If you need some help with your emergency response plan don’t hesitate contact me.

Links: Ready

First point to consider in fires of steel-framed buildings (2/11)

The time

Tic, tac, tic, tac…The bell rings and the firefighters go to the fire but, for how long has been the fire running?

This is the most important question we have to ask ourselves when we go to fire in a steel-framed buildings.

We can estimate approximately when the fire has started but it depends if it occurs in the morning, in the afternoon, in the evening or at night. The most difficult task is estimate the fire time at night.

But how could we try to prevent an accident and save our lives in steel framed buildings?

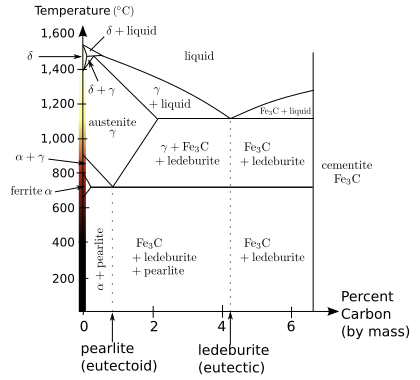

Firstly, I’m going to analyse the steel composition in order to know how the material behaviour is in high temperatures.

Analyzing steel composition

Creep Strength

The high temperature strength of materials is generally expressed in terms of their «creep strength» – the ability of the material to resist distortion over long term exposure to a high temperature. In this regard the austenitic stainless steels are particularly good also stipulate allowable working stresses of each grade at a range of temperatures. The low carbon versions of the standard austenitic grades (Grades 304L and 316L) have reduced strength at high temperature so are not generally used for structural applications at elevated temperatures. «H» versions of each grade (eg 304H) have higher carbon contents for these applications, which results in significantly higher creep strengths. «H» grades are specified for some elevated temperature applications.

Both martensitic and precipitation hardening families of stainless steels have high strengths achieved by thermal treatments; exposure of these grades at temperatures exceeding their heat treatment temperatures will result in permanent softening, so again these grades are seldom used at elevated temperatures.

Structural Stability

The problem of grain boundary carbide precipitation was discussed under intergranular corrosion. This same phenomenon occurs when some stainless steels are exposed in service to temperatures of 425 to 815°C, resulting in a reduction of corrosion resistance which may be significant. If this problem is to be avoided the use of stabilised grades such as Grade 321 or low carbon «L» grades should be considered.

A further problem that some stainless steels have in high temperature applications is the formation of sigma phase. The formation of sigma phase in austenitic steels is dependent on both time and temperature and is different for each type of steel. In general Grade 304 stainless steel is practically immune to sigma phase formation, but not so those grades with higher chromium contents (Grade 310) with molybdenum (Grades 316 and 317) or with higher silicon contents (Grade 314). These grades are all prone to sigma phase formation if exposed for long periods to a temperature of about 590 to 870°C. Sigma phase embrittlement refers to the formation of a precipitate in the steel microstructure over a long period of time within this particular temperature range. The effect of the formation of this phase is to make the steel extremely brittle and failure can occur because of brittle fracture. Once the steel has become embrittled with sigma it is possible to reclaim it by heating the steel to a temperature above the sigma formation temperature range, however this is not always practical. Because sigma phase embrittlement is a serious problem with the high silicon grade 314, this is now unpopular and largely replaced by high nickel alloys or by stainless steels resistant to sigma phase embrittlement, particularly 2111HTR (UNS S30815). Grade 310 is also fairly susceptible to sigma phase formation in the temperature range 590 to 870°C, so this «heat resistant» grade may not be suitable for exposure at this comparatively low temperature range and Grade 321 is often a better choice.

In the following video we can see how the structural stability is affected and finally the building collapse.

[youtube]8XMTALBYRNA[/youtube]

Environmental Factors

Other factors which can be important in the use of steels for high temperature applications are carburisation and sulphidation resistance. Sulphur bearing gases under reducing conditions greatly accelerate the attack on stainless alloys with high nickel contents. In some instances Grade 310 has given reasonable service, in others grade S30815, with a lower nickel content is better, but in others a totally nickel-free alloy is superior. If sulphur bearing gases are present under reducing conditions it is suggested that pilot test specimens be first run under similar conditions to determine the best alloy.

Thermal Expansion

A further property that can be relevant in high temperature applications is the thermal expansion of the particular material. The coefficient of thermal expansion is expressed in units of proportional change of length for each degree increase in temperature, usually x10-6/°C, μm/m/°C, or x10-6cm/cm/°C, all of which are identical units. The increase in length (or diameter, thickness, etc) can be readily calculated by multiplying the original dimension by the temperature change by the coefficient of thermal expansion. For example, if a three metre long Grade 304 bar (coefficient of expansion 17.2 μm/m/°C) is heated from 20°C to 200°C, the length increases by:

3.00 x 180 x 17.2 = 9288 μm = 9.3 mm

The coefficient of thermal expansion of the austenitic stainless steels is higher than for most other grades of steel.

Analyzing the Cardington Test

In the slide 31, we can see that the highest temperature was achieved in 57 minutes, if I know exactly when the fire started I can find out approximately which the structure situation is. But if I don’t know this task and I have to go into the building to rescue a person, how could I do this with security? In that case we will need to be able to read the structure signals.

Thermo-cameras

Thermo-cameras are frequently used in firefighter services, we can use this great tool to analyse the structure situation.

The slide 32 show how can we notice the difference between heating and cooling, the squares of the structure are the last part of the structure in heating and the last in cooling, in fact we can estimate what phase occurs at the moment. Moreover, with the thermo-camera we can see which the beam temperature is and know how it is affected.

But it isn’t enough to determinate the security into the structure, there are other points we must be able to evaluate to guarantee the success in this kind of emergency, we will see the second point in the next post. Please leave your comment, I would be grateful for your feedback.

Source: Atlas Steels Australia

10 points to consider in fires of steel-framed buildings (1/11)

The Cardington Fire Tests were a series of large-scale fire tests conducted in real steel-framed structures at the village of Cardington, Bedfordshire, England.

Funded by the Secretary of State for the Environment, Transport and the Regions Partners in Technology, the BRE Centre for Fire Safety Engineering (previously the Structures in Fire Group) at the University of Edinburgh conducted the experimental series in 2000. After the test, the group conducted extensive computational and analytical studies of the behaviour of steel-framed composite structures in fire conditions. This work was undertaken in collaboration with the Corus Group and Imperial College London.

In the following video you can see a sequence of the test in 2003.

[youtube]iFhjTUuD5Vc[/youtube]

the next slides show a resume of this work and which are the hot points of this research.

This research is very important for firefighters as they can know approximately how long they will be able to stay into the structure before it collapses. But… Which are the most important points you should consider to make ready this attack? Leave your comment.

Links: Cardington test reports , The Cardington and Broadgate Fires.

Atlas, iron firefighter.

Sometimes firefighters have to risk their lives in many situations that there is no survive possibilty. For this reason, Pentagon has started a competition to develop a robot which will be able to work in extremely hazardous situations.

He is a hydraulically powered robot and they call him Atlas. The Pentagon-financed humanoid robot was unveiled to the public today.

His mission is as noble as it gets: help rescue missions in cases of natural and man-made disasters, especially in situations where humans cannot survive – the ultimate firefighter, that is.

And some of its features include laser and stereo vision systems, as well as dexterous hands.

The Pentagon has put on a challenge in which competing teams of technologists program it to do things like shut off valves or throw switches, open doors, operate power equipment and travel over rocky ground. The winner will be rewarded with a $2 million check.

¿It´s that the beginning of the end of firefighters?, I would like to known your opinion, leave your comment.

[youtube]zkBnFPBV3f0[/youtube]

Links: Nature world new, Atlas.